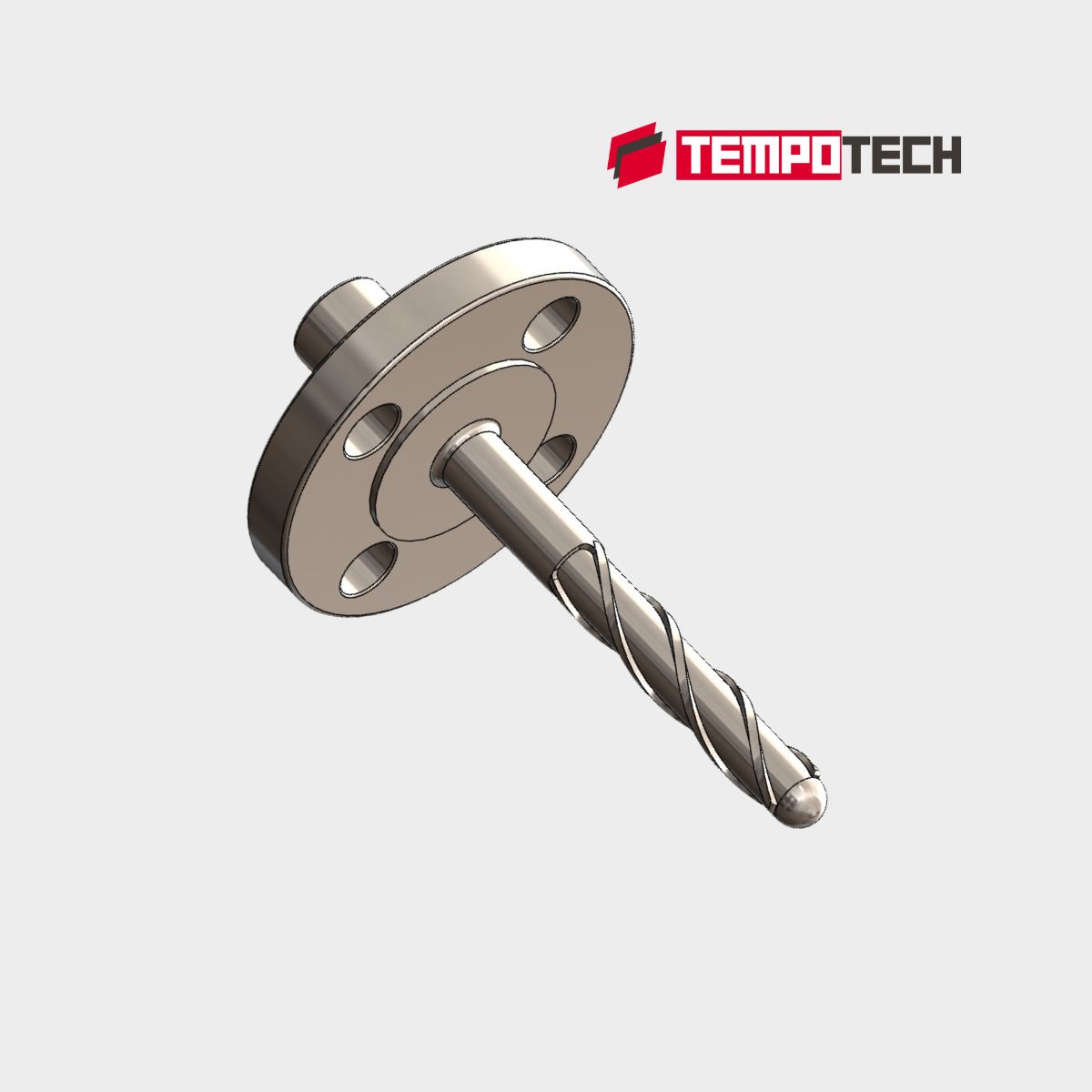

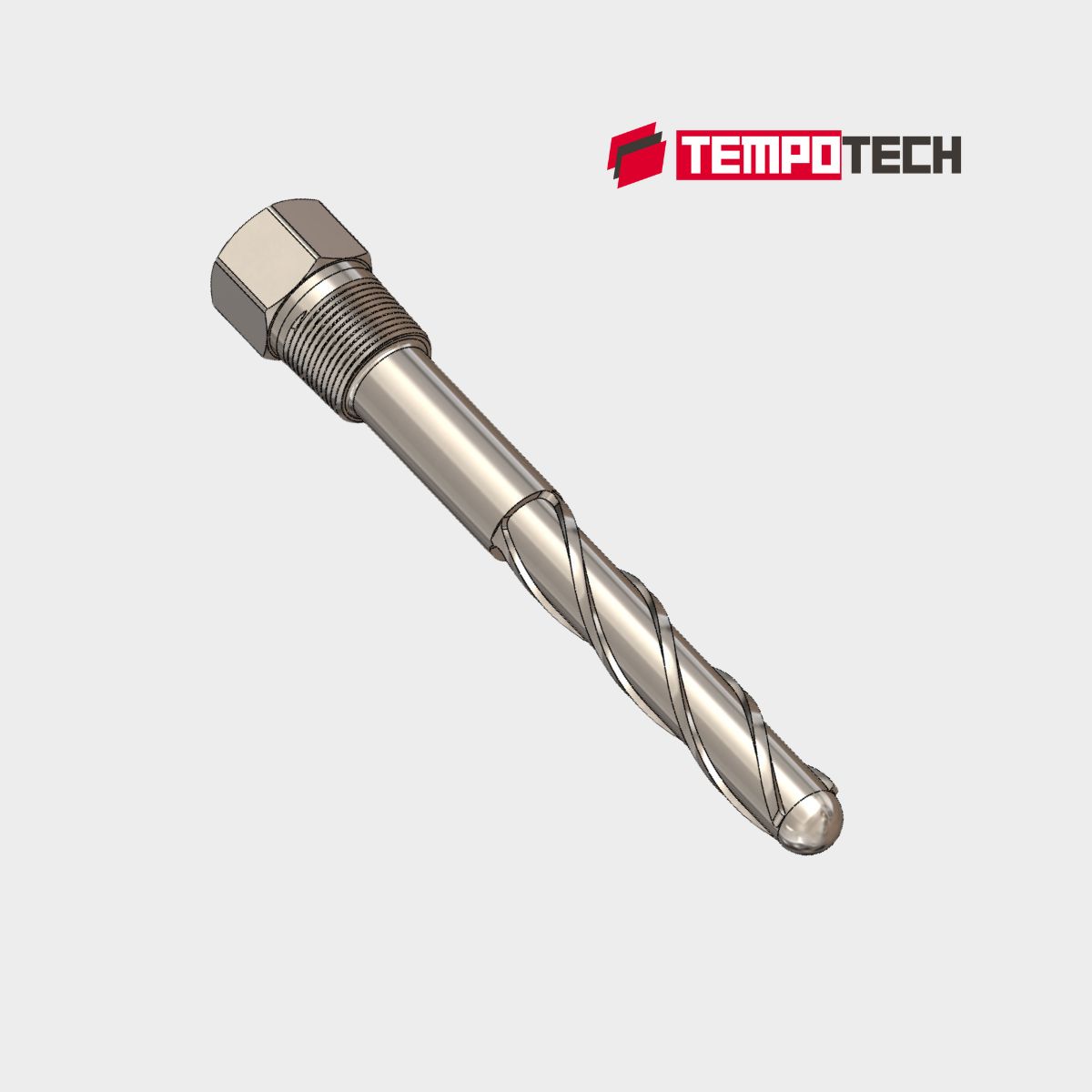

To avoid thermowell damage from mechanical loads, it is suggested performing a wake frequency calculation according to ASME PTC 19.3 TW-2016 standards for critical processes. If results are negative, solutions like shortening the thermowell stem or increasing root and tip diameters can be considered, though they may slow response time. Alternatively, a support collar stabilizes the thermowell stem within the flange nozzle but requires on-site machining. Tempotech’s Helical design reduces oscillation amplitude by over 90%, enabling quick, easy installation without a support collar, saving time and cost. .

Key features:-

- Material 316,304,310,321,347, Alloy 20 , C-276,Inconel 800, Inconel 600 ,625, 825 , Monel 500 Titanium ( See Data Sheet)

- Fast Response as small root and tip diameters

- Heavy Duty desgin

- Less limitations due to Immersion length

- Socket, flanged, threaded,vanstone thermowell avaiable with helical style.

Application Note

Tempotech’s helical series thermowells are designed to meet the demanding conditions of the petrochemical industry, on-/offshore operations, and plant construction. Built to withstand high process loads, these thermowells provide reliable performance in extreme environments, protecting temperature sensors from aggressive media, high pressures, and rapid flow rates