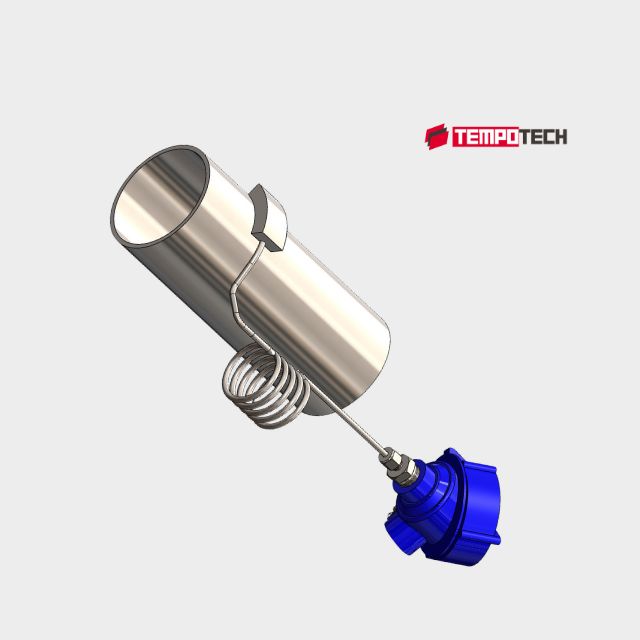

TC60-2 Tube skin sensors manufactured by Tempotech Controls are precision-engineered devices specifically designed to y measure accurate temperature of tube walls in the chemical power and petroleum industries. These thermocouples play a critical role in monitoring boiler and superheater, heat exchanger operations within power plants, Boilers, Chemical processing where precise temperature readings are essential for assessing thermal fatigue and the integrity of tube materials under high-pressure conditions. The sensors are fabricated using high-quality sheath material that ensures exceptional thermal insulation while accommodating necessary expansion loops. This feature facilitates seamless installation and optimizes the sensors’ functionality across various applications, thereby enhancing their longevity and reliability. The weld pads are designed to align with a wide range of tube materials such as Inconel, Monel, Pyrosil, Molybdenum etc and can withstand extreme temperaturesof up to 2100°F. Extreme temperature rated material makes them suitable for demanding high-temperature environments where durability is crucial.

Key Feature:-

- Available in type J, K, E, N, T .

- wide selection of sheath material to suit application requirement, 304ss, 316ss, 321ss, Inconel® 600, Incolloy 800, Monel, Pyrosil D etc.

- Sheath diameter is available from 0.125″ to 0.500″

- Standard weld pad size 1″x1″x1/8″ , custom size also available

- Available with Explosion proof enclosure CSA, ATEX, FM .

- Grounded, and Ungrounded junction to meet application requirement.

- Available with low temp and high temp connectors.

- Available in IEC 60584 & ANSI MC 96.1 standard tolerances

![]()

Application Note

TC60-2 is an ideal choice to measure the surface temperature of pipelines containing steam, gas, and fluid to monitor thermal gradients and ensure safe operating conditions.Wall surface temperatures of pressure vessels, reactors, and storage tanks to detect hotspots or thermal stress. Temperature measurement of heat exchanger tubes and shells to optimize thermal transfer efficiency. Temperature monitoring on boiler tube surface and furnace walls is done to prevent overheating and corrosion. Continuous temperature monitoring in process control in industries like petrochemicals, fertilizers manufacturing, and power generation.