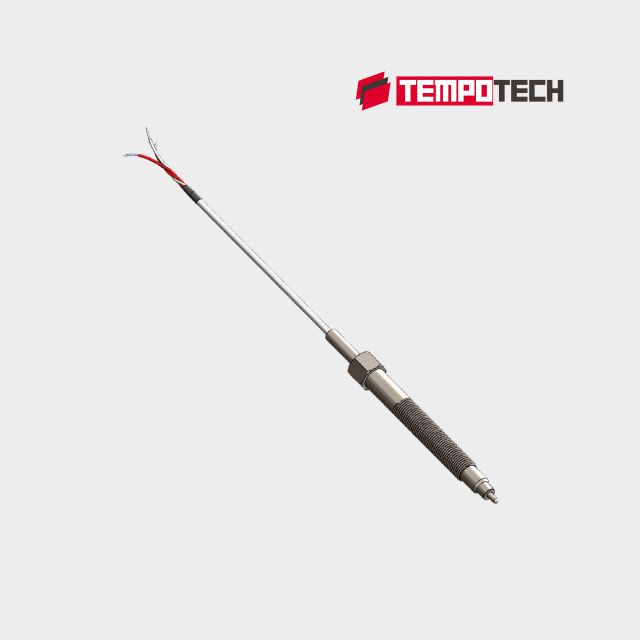

The RTD23 series from Tempotech Controls, featuring a melt-bolt design, is used in extruders and injection molding machines to directly measure the melt temperature of plastic as it flows through the extruder barrel.). For applications requiring specific materials, values, or tolerances, customized elements are available upon request. The RTD23 offers accurate and reliable temperature measurement, ensuring efficient control of plastic melt temperatures in various manufacturing processes.

Key features:-

- Available in type Pt100,Pt100(0.00392),Pt200,Ni20 ohm .

- Available in Class B, Class A, Class AA, 1/10 DIN B(IEC 60751& ASTM E1137)

- Single and Duplex Sensor elements.

- Range -50°C to 510°C ( -58°F to 950°F)

- Bolt Length 3″,6″,9″ and 12″

- Bare ends and Connector option avaible

- TEFLON (200°C and fiberglass wire 480°C with SS braiding and Armours available

Application Note

The RTD23 series from Tempotech Controls is specifically designed for the plastic industry, providing reliable temperature measurements. These nozzle-style RTD sensors are ideal for monitoring temperatures in injection molding processes, ensuring precise control of the nozzle temperature without direct contact with molten plastic. The RTD23 is also well-suited for surface temperature measurement, offering accurate readings in various applications, such as heat plates and sealing bars. With its robust design and customizable configurations, the RTD23 provides versatility and reliability in critical temperature monitoring for plastic manufacturing processes.